Situation

Pumps evacuate the pharmaceutical fermenter and run dry

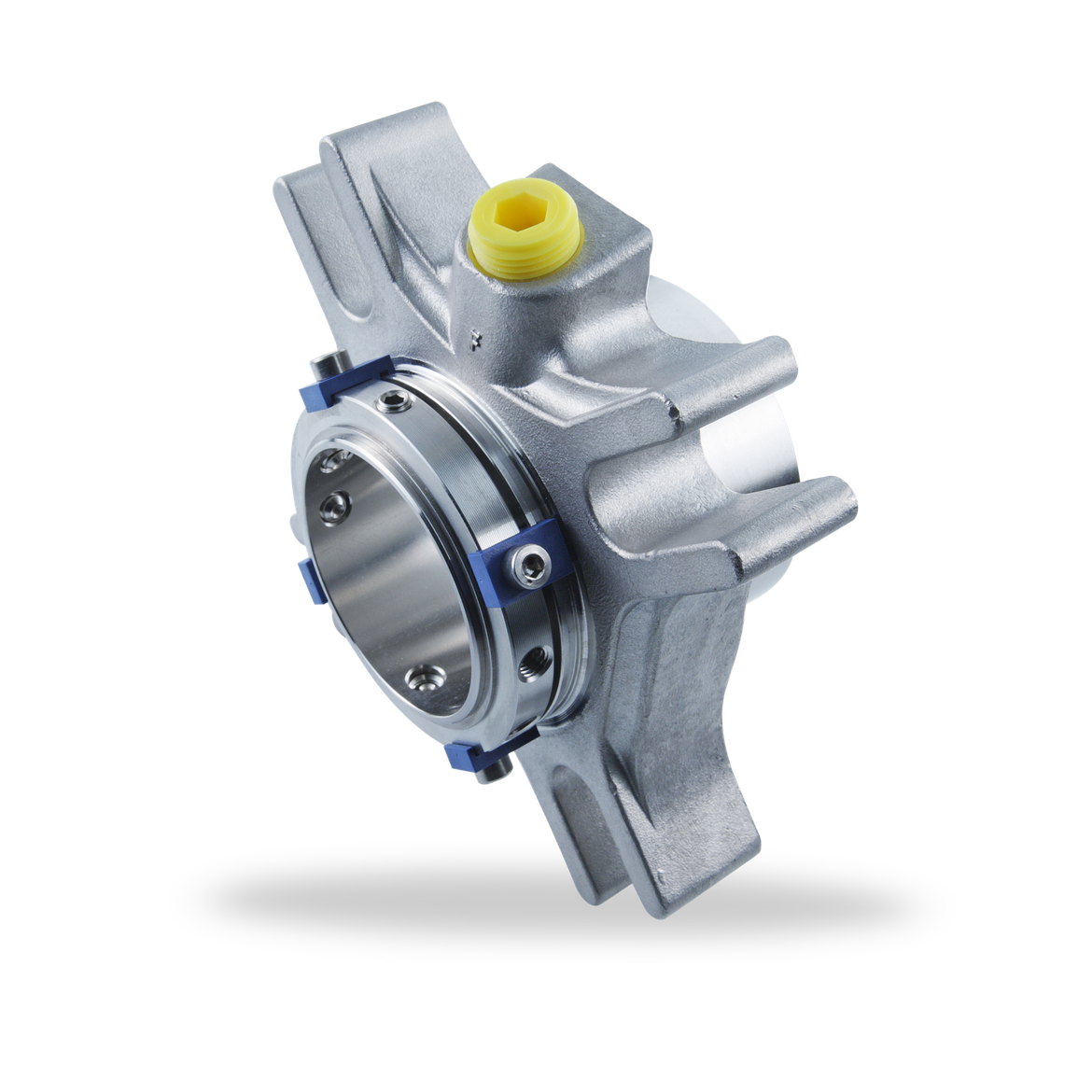

Single seal Cartex-SN with DiamondFace for high pressure centrifugal pumps in the pharmaceutical industry

Pumps evacuate the pharmaceutical fermenter and run dry

Automated processes, leakage value may not be exceeded

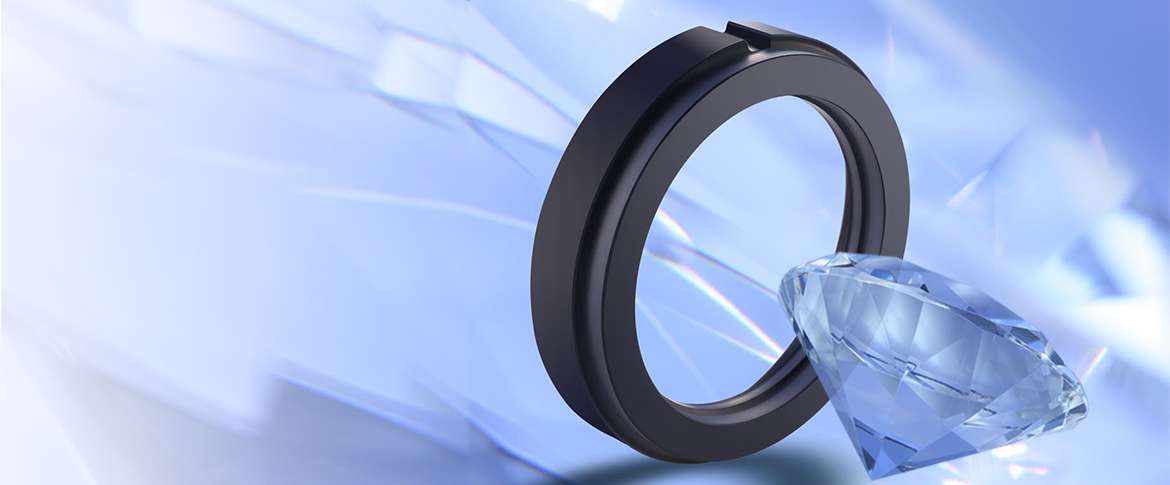

Cartridge seal Cartex with DiamondFace coating by EagleBurgmann

Roughly 400 pump shafts are equipped with mechanical seals from EagleBurgmann at the production site of a pharmaceutical company. Constantly changing operating conditions and dry running phases place extreme demands on the seals. DiamondFace technology significantly extends service life and reduces stock costs through further rationalisation.

This pharmaceutical company in Great Britain produces active substances by a fermentation process for the production of antibiotics. End suction centrifugal pumps according to ANSI specification transfer the medium between vessels. During the process one vessel is completely evacuated by the pumps, causing them to run dry and leaving the seals with insufficient or no lubrication at all. Both the production personnel and the control systems cannot intervene quickly enough to respond in time to dry running as the process is automated.

No standard single mechanical seal can withstand dry running at the speeds involved here and dry running of pump seals accounted for 80 % of the failures on site. Since the production site uses many solvents as a carrier within the process, only standard leakage can be tolerated, any more is classed as a “loss of containment” which can be reportable.

As the production process has very few standby pumps, any increases in the MTBF interval (MTBF: Mean Time Between Failures) are highly appreciated. Today EagleBurgmann’s DiamondFace technology is providing a significant benefit.

Some years ago, the customer and EagleBurgmann signed a “TotalSealCare” contract and started to convert all pumps from component seals to “Cartex” seals, i.e. cartridge single and doubles seals. Principally Cartex single seals are installed on the pump shafts to prevent egress of the process fluids. These mechanical seals are completely pre-assembled and precisely positioned component seals with cover plate and shaft sleeve. The cartridge design allows for quick and easy installation and makes it difficult for dirt to enter during assembly. Construction of this seal complies with the requirement for minimum downtimes in production as well as with the high degree of purity required in the pharmaceutical industry. It also provides a platform for stock rationalization and FDA compliance where necessary.

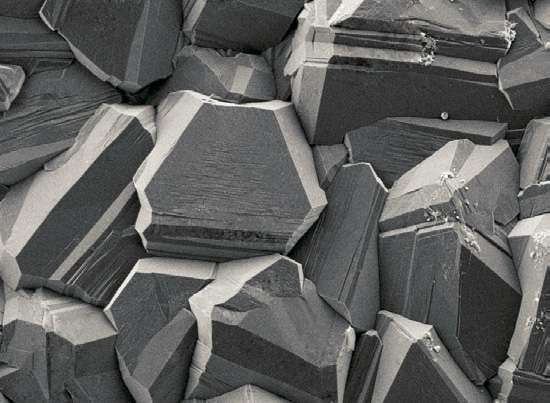

One of the next steps was to optimize the Cartex seals by using DiamondFace technology: A special procedure provides the surfaces of the seal faces with a microcrystalline coating of artificially produced diamond, making them extremely wear-resistant and capable of partial dry running. Furthermore, very little heat is generated during the dry running phases.

The concept has been tried and tested. In the meantime, the DiamondFace version of the Cartex single seal is being installed bit by bit in the pumps. Not only have the costs for the seals been noticeably reduced, but so have the costs for new shaft bearings and shafts. The MTBF interval has increased one hundred percent from two to four years. The risk of costly production interruptions has been significantly reduced. From now on, all single seals are to be supplied with DiamondFace sliding surfaces as standard.

There is another decisive advantage to DiamondFace. It only requires one material combination for the seal faces, allowing the stock held on site to be reduced from 24 parts to eight parts per seal. Additional standardization measures in sealing design and material combination have enabled EagleBurgmann to reduce the site stock over the years from 900 individual parts to 150 complete seals. The number of stores inventory locations has been streamlined from 22 to six.

EagleBurgmann and the pharmaceutical company have been working together since 2002. Extended operating periods and increased reliability of the Cartex-SN as well as reduced storage costs, training and 24/7 support have encouraged the customer to continue to rely on EagleBurgmann as their supplier of all sealing solutions.

Would you like to learn more about our range of products & services we offer to the pharmaceutical industry? Find our more here. Or feel free to contact us.

Single seal Cartex-SN with DiamondFace for high pressure centrifugal pumps in the pharmaceutical industry.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

Special expansion joints from EagleBurgmann compensate for these position changes and work reliably even under unfavorable conditions such as low temperatures, proximity to the sea and explosive environments.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.

The new zero-emission mechanical seal from EagleBurgmann prevents the emission of the greenhouse gas methane during natural gas extraction, transport and processing.

The reliability of centrifugal compressors in gas grids are of the highest social and economic importance for network operators. Compressor performance and availability are closely related to the effectiveness of sophisticated compressor shaft sealing technology. Here, EagleBurgmann developed a new sealing concept which ensures better compressor availability: the coaxial separation seal CobaSeal.